Steel making equipment refers to equipment and mechanical devices used in steel production, whose function is to convert raw materials in the production process into high-quality steel products. Steel making equipment plays an important role in steel production, as it can complete multiple processes such as steel production, processing, and testing, thereby improving the efficiency and quality of steel production. The following will provide a detailed introduction to the role of steelmaking equipment in steel production.

Firstly, steelmaking equipment plays a crucial role in the raw material processing process. In steel production, raw materials usually include iron ore, scrap steel, scrap iron, etc. Steel making equipment converts raw materials into high-quality steel raw materials through multiple processes such as ore crushing, ore leaching, mixing, and smelting. Steel making equipment can perform operations such as screening, crushing, and magnetic separation on raw materials to separate and purify them, ensuring that the quality and iron content of the raw materials meet production requirements.

Secondly, steelmaking equipment plays a core role in the smelting process. Smelting refers to heating raw materials and reacting them with fuel to undergo chemical changes, resulting in the production of finished steel products. Steel making equipment includes various types such as blast furnaces, electric furnaces, and converters. The blast furnace is the most important smelting equipment, which reduces iron containing raw materials into liquid pig iron through reduction reactions at high temperatures. Electric furnaces use electricity to heat and melt scrap steel, then add appropriate alloying elements to generate finished steel products. The converter uses an oxygen blowing furnace to remove impurities from the molten steel and improve its purity. These steelmaking equipment can control parameters such as temperature, atmosphere, and material flow during the smelting process, ensuring that the quality and composition of steel products meet the requirements.

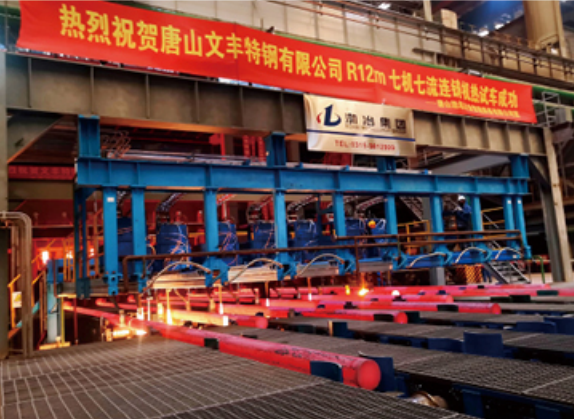

Once again, steelmaking equipment plays an important role in the continuous casting process. Continuous casting refers to the process of continuously casting molten steel into shape. The continuous casting machine in steelmaking equipment is one of the main equipment for achieving continuous casting. The continuous casting machine pours steel liquid into the crystallizer, rapidly cools the steel liquid through the cooling water in the crystallizer, and solidifies it into a billet. The advantages of continuous casting are high production efficiency, high product dimensional accuracy, and energy conservation. The steelmaking equipment can control the pouring speed, crystallizer temperature, cooling water flow rate and other parameters of continuous casting, ensuring the stability of billet quality and size.

In addition, steelmaking equipment also plays an important role in the steel processing process. Steel processing refers to the process of further processing continuous casting products into the required steel products. The rolling mill in steelmaking equipment is one of the main equipment for steel processing. The rolling mill rolls the billet through multiple passes to form the required specifications of steel products. Different types of rolling mills can produce steel of different shapes, such as hot rolling mills that can produce plates, hot rolled strips, etc., and cold rolling mills that can produce cold rolled strips, cold rolled sheets, etc. Steel making equipment can control parameters such as rolling force, rolling speed, and rolling temperature of the rolling mill, ensuring that the surface roughness, dimensional accuracy, and mechanical properties of steel products meet the requirements.

In addition, steelmaking equipment also plays a role in quality inspection and environmental protection in the steel production process. Quality inspection equipment and instruments in steelmaking equipment can detect steel products, including composition analysis, dimensional testing, mechanical performance testing, etc. These quality inspection equipment can ensure that the quality of steel products meets standards and customer needs. Meanwhile, steelmaking equipment also includes environmental protection equipment and measures, such as smoke and gas

Customer service hotline

400-1760-789

Tangshan Bohai Metallurgical (Group) Co., Ltd., China

Address:No. 11 Kaisan Road, High tech Industrial Park, Tangshan City, Hebei Province, China

Postal Code: 063020

Contact number:+86-315-5923161/5923167

Fax:+86 315 5934590

Website:http://www.tsbyjt.com

E-mail: tsbhyj@126.com