The converter refining system is one of the important equipment and process flows in steel production. As the core equipment of the metallurgical industry, it heats scrap steel, pig iron, and other raw materials to high temperatures for dissolution, reaction, and tempering, ultimately producing high-quality steel. The converter refining system mainly includes the following aspects:

Blast furnace tapping: Blast furnace tapping is one of the pre production processes in converter production. The blast furnace produces pig iron and slag by smelting raw materials. The pig iron in the blast furnace will be used as one of the raw materials for the converter for further refining and smelting.

Converter body: The converter body is the core part of the converter refining system and serves as a container for smelting and refining. Usually, a converter consists of a cylindrical shell, a tilting mechanism at the bottom, injection and expansion devices, bottom blowing, side blowing, and other parts.

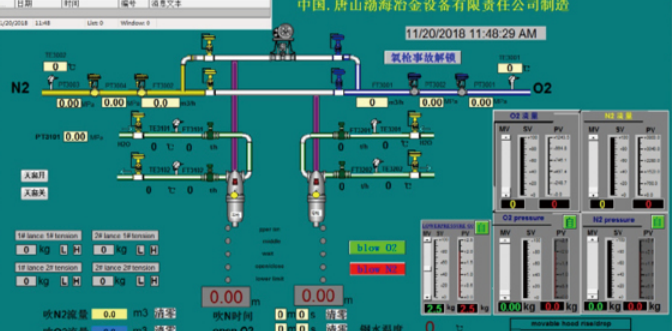

Converter operating system: The converter operating system is an important tool for achieving converter control and automation. It includes computer systems, sensors, actuators, monitoring equipment, etc. Through the converter operating system, real-time monitoring and control of parameters such as temperature, pressure, injection rate, and oxygen content can be carried out to ensure good smelting efficiency of the converter.

Spray device: The spray device is an important component of converter refining. It introduces high-speed airflow into the furnace body by injecting media such as oxygen and nitrogen to promote chemical reactions, combustion, and mixing processes. The spraying device in the converter usually includes an intermediate blowing port, a bottom blowing port, etc.

Argon blowing device: The argon blowing device plays a role in stabilizing temperature, dissolving impurities, and reducing oxidation during the refining process of the converter. The argon blowing device blows argon gas through the bottom of the furnace to form an argon gas bag, protecting the steel liquid from oxygen pollution.

Slag treatment system: Slag treatment is an essential part of the converter refining process that cannot be ignored. The slag treatment system separates and processes the slag generated by the converter through equipment such as slag trucks and slag tanks to ensure the quality of the steel liquid and the normal operation of the converter.

Feeding system: The feeding system is a key feeding equipment in converter refining. Through the feeding system, raw materials such as pig iron, scrap steel, decarburizer, desulfurizer, etc. can be added to the converter as needed to adjust their composition and performance.

Detection system: The detection system is a very important link in the converter process. By using chemical analyzers, thermometers, pressure gauges, gas analyzers and other equipment, the gas, temperature, composition and other parameters of the converter can be monitored and analyzed to ensure the accuracy and stability of converter operation.

The converter refining system integrates various equipment and process flows. Through reasonable control and operation, it can achieve the goals of resource utilization of scrap steel, optimization and adjustment of steel composition, removal of impurities, etc., improve the quality and smelting efficiency of steel, reduce energy consumption and environmental pollution, and play a crucial role in the development of the steel industry.

Customer service hotline

400-1760-789

Tangshan Bohai Metallurgical (Group) Co., Ltd., China

Address:No. 11 Kaisan Road, High tech Industrial Park, Tangshan City, Hebei Province, China

Postal Code: 063020

Contact number:+86-315-5923161/5923167

Fax:+86 315 5934590

Website:http://www.tsbyjt.com

E-mail: tsbhyj@126.com